TYPES OF CARPET CUSHION

There are 3 basic types of cushion:

Each type is further subdivided into two or three varieties. Each variety has characteristics that make it useful for specific types of carpet installation. Each variety also has grades, which vary by weight (also referred to as density), thickness, and the amount of force it takes to compress the cushion.

Density is one of the most important parameters of any type of cushion. Density equals weight divided by thickness, and its measured in pounds per cubic foot. All types of cushion can be made dense (more material), or light (more air), or any grade in between, so they can be soft or firm, resilient or supportive, according to the type of room and expected traffic on the carpet they support.

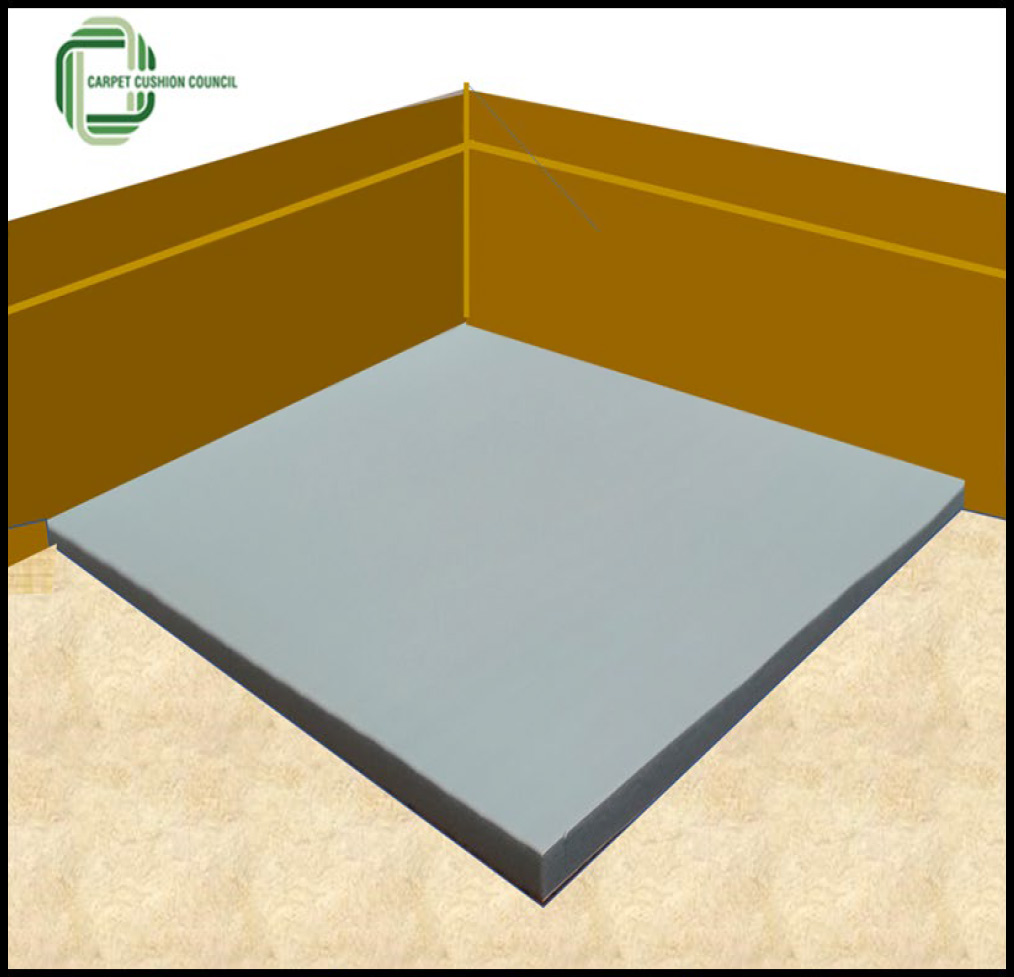

Prime Polyurethane Carpet Cushion |

||||

|

Prime polyurethane foam is a firmer version of the same cushioning used in upholstered furniture, mattresses, and automobile seats. Two liquid ingredients are combined to form a block of foam, which is then sliced into sheets for use as carpet cushion. Alternatively the mixed foam ingredients foam may be poured in the form of a continuous sheet, |

Cross-sectional views

High firmness foam cut from blocks and laminated with webbing and a plastic film.

Molded prime cushion with plastic film on both faces to facilitate installation and prevent moisture transmission. |

||

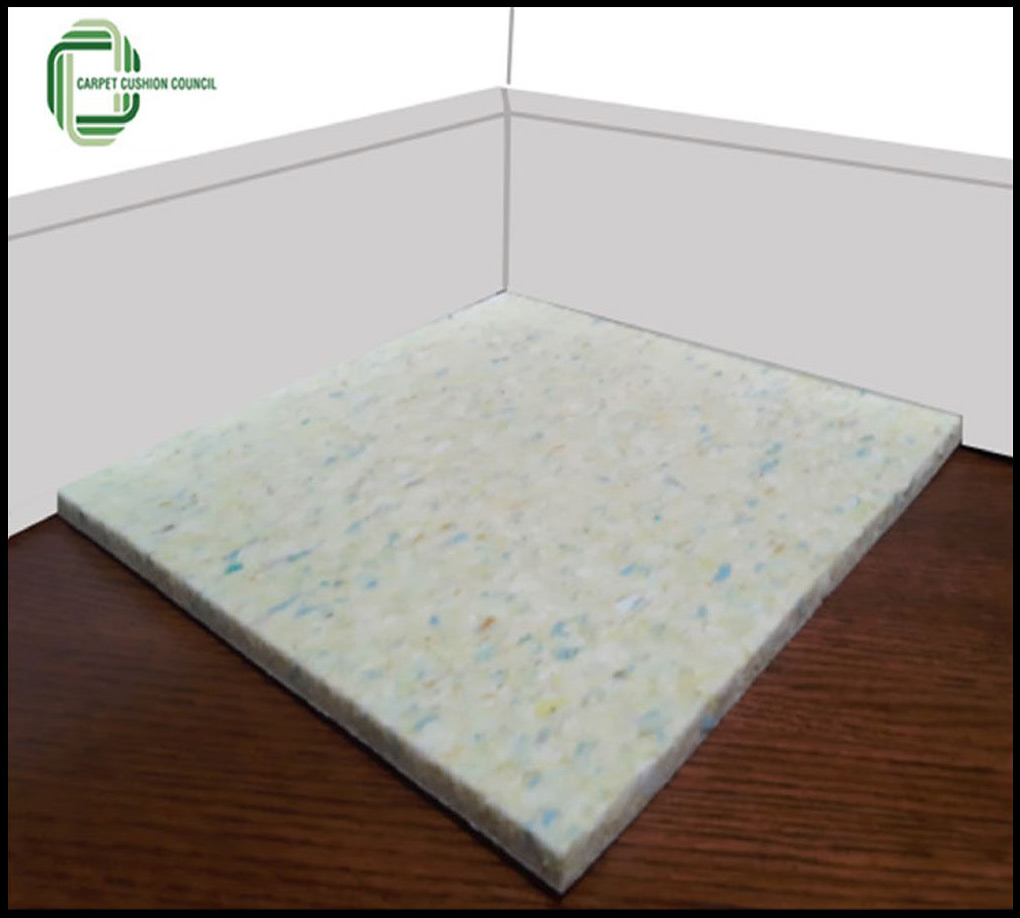

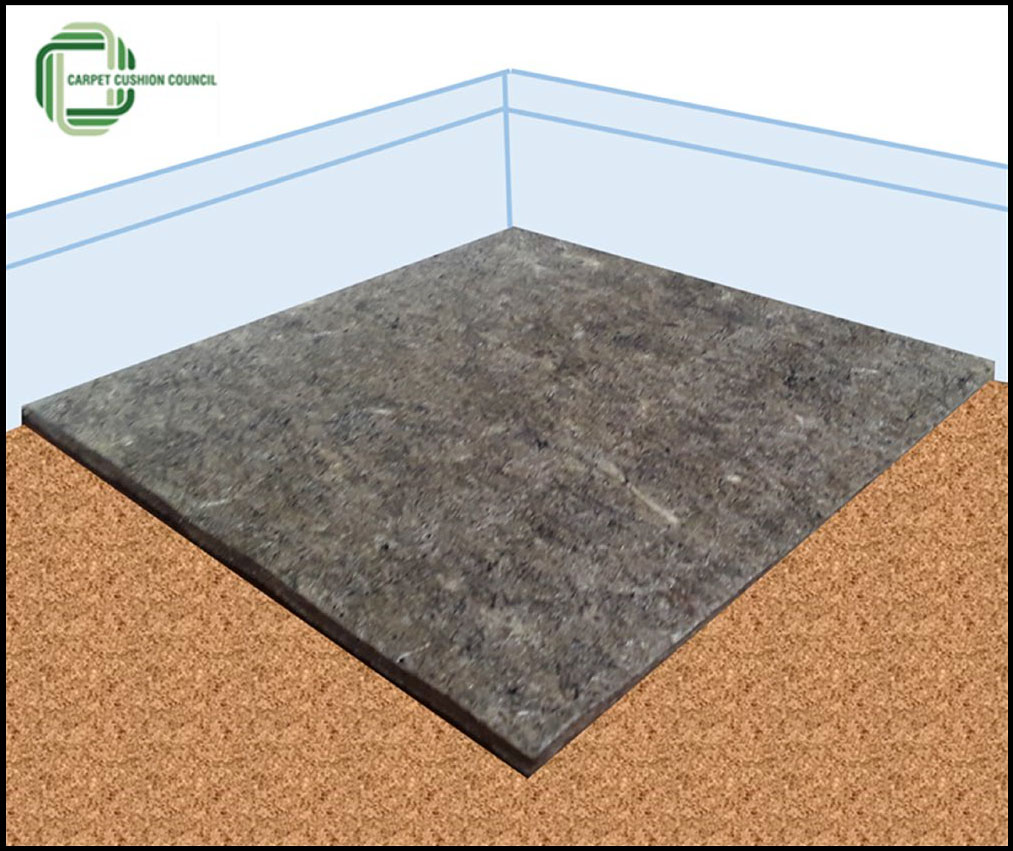

Bonded Polyurethane Foam Carpet Cushion |

||||

|

Bonded polyurethane foam (also called rebond) is quite unique. It is easy to recognize, because it is formed by combining small chopped foam pieces, of different sizes and usually different colors, into one solid piece. It frequently has a surface net for ease of installation and improved performance. Bonded foam is one of the most amazing recycling projects of all time. Post-consumer and post-industrial scrap foam in the U.S., and some from other countries, is utilized to make bonded cushion. This recycles materials which would otherwise be discarded, and it eases the strain on our landfills. Moreover, bonded foam is itself recyclable. |

Cross-sectional view

Small pieces of surplus flexible foam bonded together with a polyurethane adhesive and laminated with scrim or a film to prevent moisture transmission. |

||

Polyolefin Foam Carpet Cushion |

||||

|

Polyolefin foam is made using thermoplastic processing equipment. Polymer is combined with blowing agents and other ingredients and extruded as ready to use sheet or block for cutting into sheet. |

Cross-sectional view

Cross-linked polyolefin (polyethylene or polypropylene) continually extruded as foamed product available in a range of densities and thickness. |

||

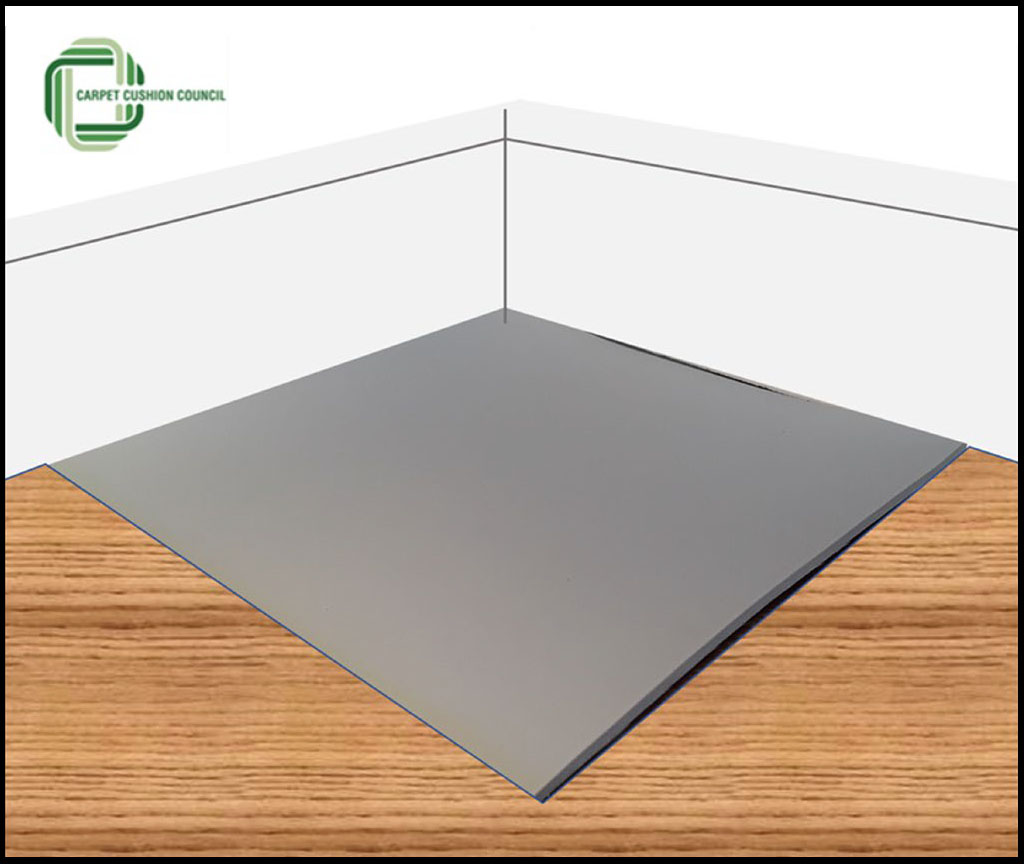

Mechanically Frothed Polyurethane Carpet Cushion |

||||

|

Froth polyurethane foam is made using carpet backing machinery. Liquid ingredients are applied, either directly to the back of some carpet styles, or to a non-woven material (for making separate cushion). The materials react and form a thin dense foam, which is useful for commercial applications with wide expanses of carpet. |

Cross-sectional view

Polyurethane foamed and cast directly onto carpet or a film using carpet backing machinery. |

||

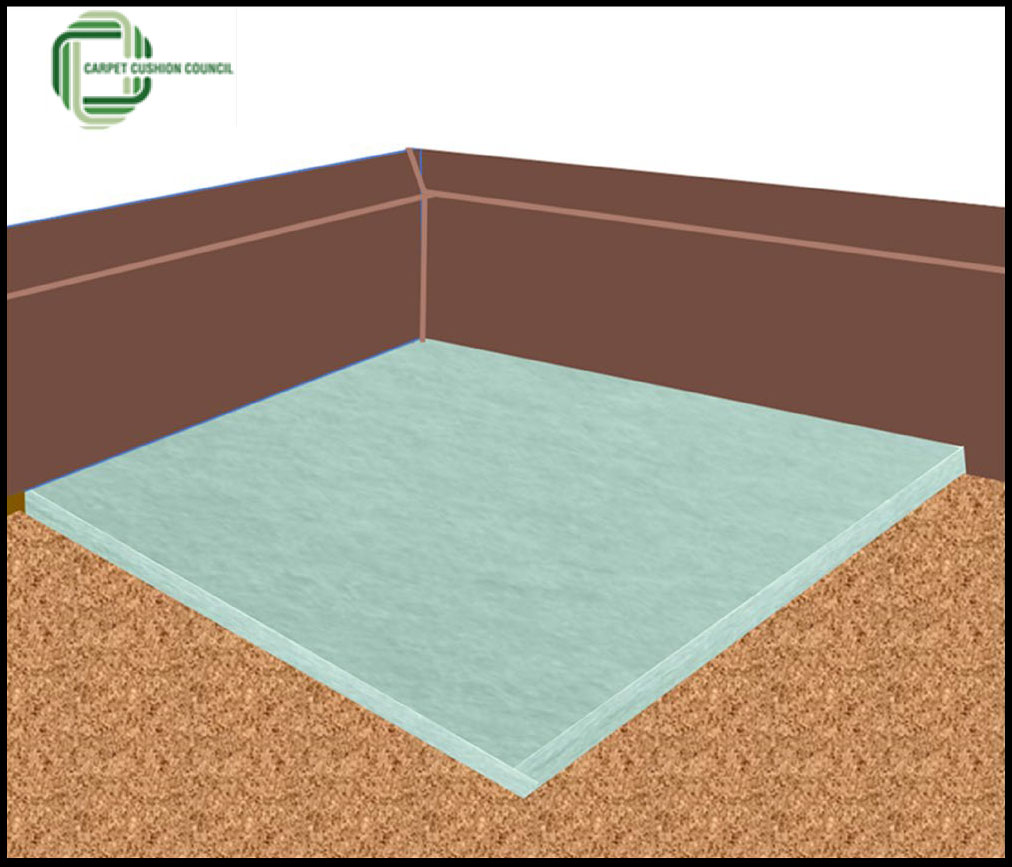

Fiber Carpet Cushion |

||||

|

Fiber cushion uses virgin and recycled natural or man-made fibers which are interlocked to produce sheet of felt. There are two distinct varieties of fiber cushion. Natural fibers include felt, animal hair, and jute This is one of the original types of carpet cushion, dating back to the earliest days of machine-made carpet. Synthetic fibers include nylon, polyester, polypropylene and acrylics, which are needle-punched into relatively dense cushions which have a firm feel and, as with other types of cushion, can be made in virtually any weight, to stand up to light, medium, or heavy traffic, which is s how they are usually classified. Fiber cushion may be produced from fiber from recycled carpet, resulting in a significant reduction in landfill use. |

Cross-sectional view Natural or synthetic fibers are made into felt by needle punching or resin bonding to produce different weight and thickness of cushions. |

||

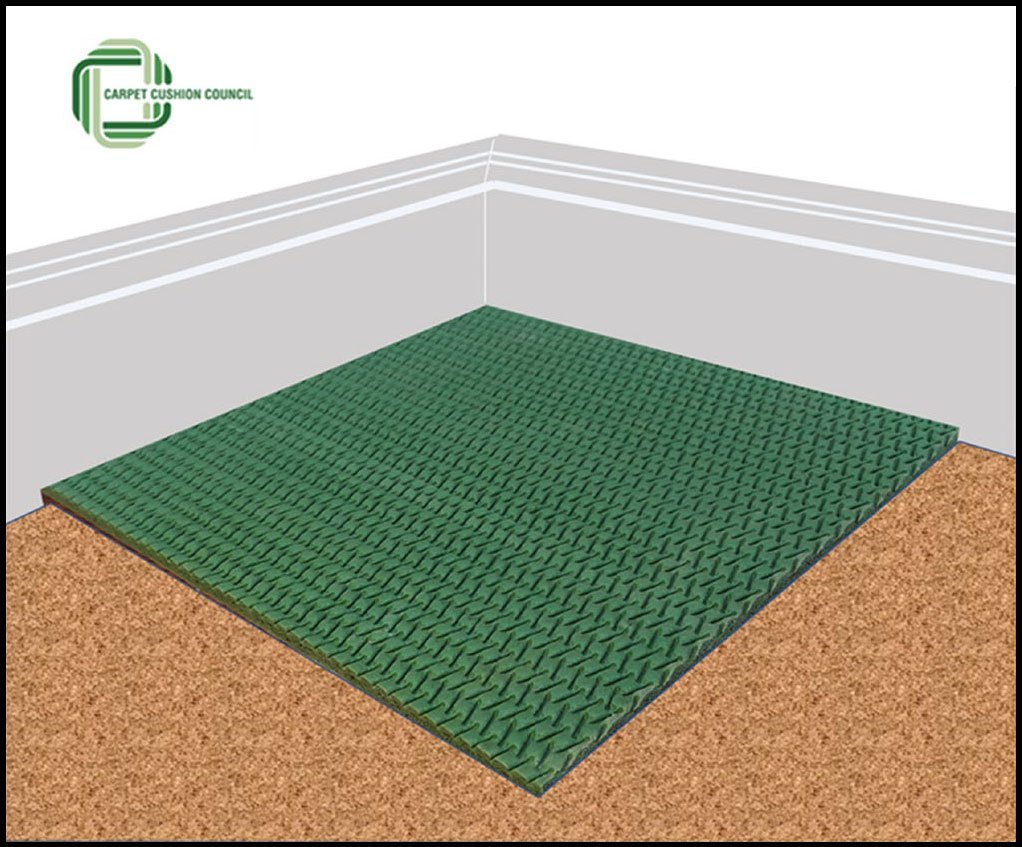

Rubber Carpet Cushion |

||||

|

Waffled rubber cushion is made by molding natural or synthetic rubber. Heat cures the rubber and forms a waffle pattern. This variety produces a soft, resilient cushion whose luxurious feel is particularly useful for residences. Flat sponge rubber is a firm, dense cushion, which has flat surface and is normally used in large-scale commercial applications and with loop type (or Berber) carpet. Rubber cushion manufacturing processes can be varied to produce different levels of density and firmness. The usual measurement is the weight in ounces per square yard. Reinforced Rubber Carpet Cushions are manufactured with an open cellular structure made from ground tire scrap rubber granules bonded with latex. Such types of cushion Represents an important step in reducing landfill use. |

Cross-sectional views

Synthetic rubber sponge is produced with flat or rippled surface in a range of weights. Another type is made from Recycled rubber granules or shreds are bonded with latex. |

||

|

Berber carpet requires a thin, firm cushion. When using this type of carpet, be sure that the accompanying cushion has been specified by the manufacturer as suitable for Berber carpet. Radiant heating is becoming more widely used in some areas of the country. In the case of radiant heating, avoid using a cushion that is an exceptionally effective insulator. Choose a cushion that allows the heat from the subflooring to penetrate the carpet system and heat the room. A relatively thin, flat cellular sponge rubber or synthetic fiber cushion works well under these circumstances. Retailers should ask customers if their room(s) have radiant heating. |

||||